IHTS Industries

OEM Part Designers

IHTS will partner with you to help you design stronger, lighter and less expensive heat treated or forged parts. We can recommend the heating and quenching technologies that optimize for your specific components for the end users.

IHTS will collaborates with part manufacturers to:

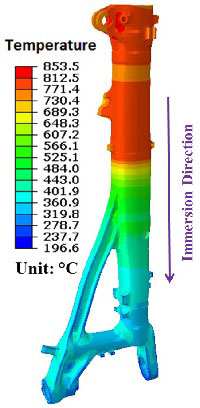

- Eliminate post-heat treatment remediation costs due to distortion

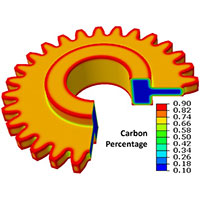

- Reduce costs by using lowering alloy content and still achieve stronger and/or lighter parts

- Avoid supply chain snags by designing parts from readily available steels or ductile irons

- Decrease part weight while simultaneously making them more durable

- Minimize heat treat distortion and post-heat treat or post-forging machining costs using our Quench2FIT™ Technologies

- Better parts and a total lower costs of manufacture and less impact on our environment

IHTS delivers Consulting Services that:

- Assess the part maker’s current situation – examining the entire supply chain for optimal materials, integrated with the right manufacturing processes and optimal heat treating processes for reducing distortion and adding more value per BTU expended

- Recommend alternative raw materials, design tweaks, lean manufacturing, all integrated with heat treating to deliver more value and eliminate waste in the customer’s existing processes

- Justify recommendations with the use of cost-benefit analysis (ROI)