IHTS integrates heat treating into part design to enable lean manufacturing. Click the link below to see how.

The Mission of IHTS is to Help Part Designers:

- Reduce material costs by creating stronger, more durable parts from lower alloy materials

- Reduce supply chain dependence by producing parts from materials that are readily available

- Reduce production costs by creating parts that eliminate post-heat treatment machining

- Reduce component weights while simultaneously increasing strength

What IHTS Provides:

Consulting with part designers to enable stronger, lighter and less expensive heat treated or forged parts

- Assess their current situation, including materials, manufacturing and heat treating processes, and distortion management

- Recommend material, design, manufacturing, heat treating and distortion improvements to their existing processes

- Justify recommendations with use of cost-benefit analysis (ROI)

Consulting with part manufacturers to design components with heat treating and quenching in mind (Quench2Fit) to help them -

- Choose the least expensive materials

- Improve part strength, durability, life, performance

- Optimize heat treatment costs by reducing cycle time and input costs

- Eliminate post-heat treat machining/remediation costs

Turnkey Solutions

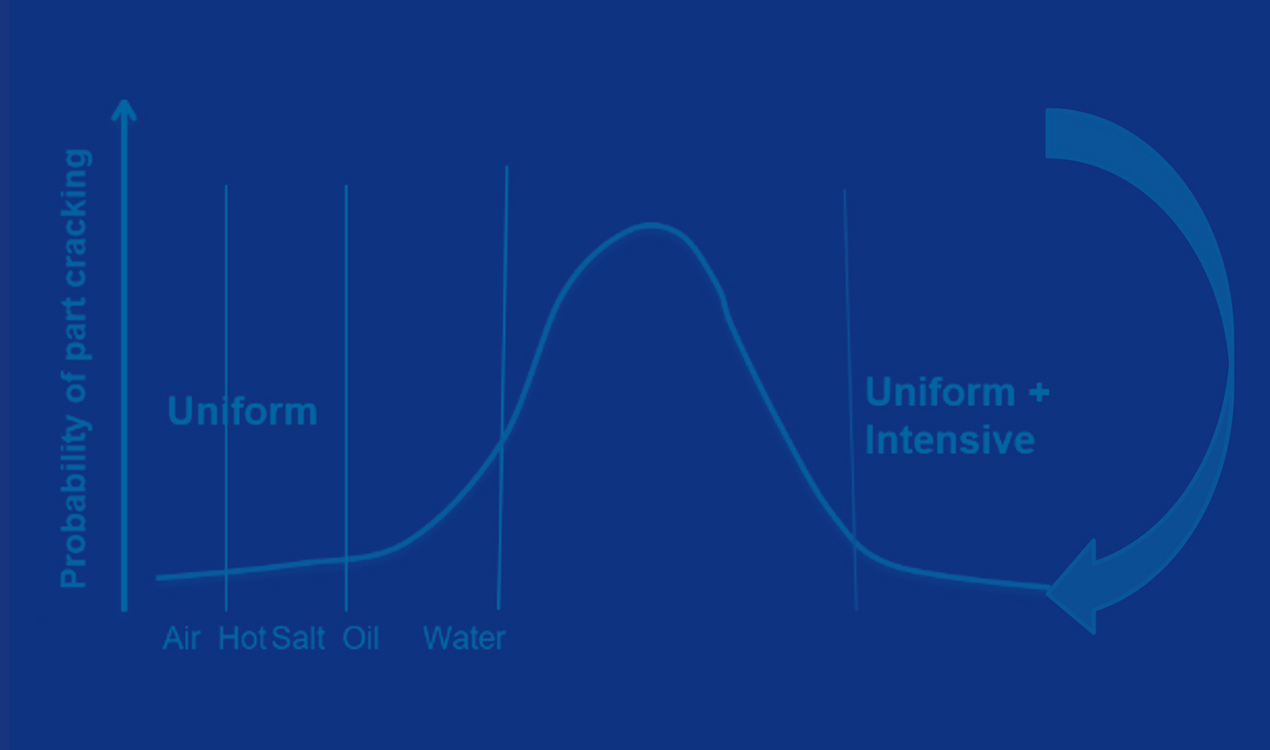

- Integrated heat treating/quenching solutions, including equipment and technology/licensed processes, in collaboration with associate entities and/or partners

IHTS's strategies are based on proven technologies over 25 years of testing, production, and continual improvement.

Finally, lean manufacturing for heat treated parts

Lean manufacturing principles hold the promise of reducing material cost and procurement headaches, eliminating manufacturing bottlenecks, and enabling stronger, lighter parts with shorter process time and less costs.

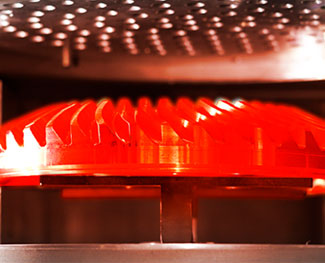

ONE-PIECE-FLOW - CASE HARDENING TECHNOLOGY FOR LEAN MANUFACTURING

"In order to establish a more effective, economic production system, the goal is to move away from batch-type logistics and toward 'one-piece-flow' production."

Bill Gornicki, Vice President, ALD-Holcroft

Naturally, we should all be moving at breakneck speed toward lean manufacturing. But until now, heat treating hasn't embraced lean manufacturing.

THE GOALS OF ASM'S VISION 2020 PUBLISHED AS PART OF THEIR

1999 RESEARCH & DEVELOPMENT PLAN INCLUDE:

- Reduce energy consumption by 80%

- Reduce process time by 50%

- Reduce production costs by 75%

- Achieve zero distortion, maximum uniformity in heat treated parts

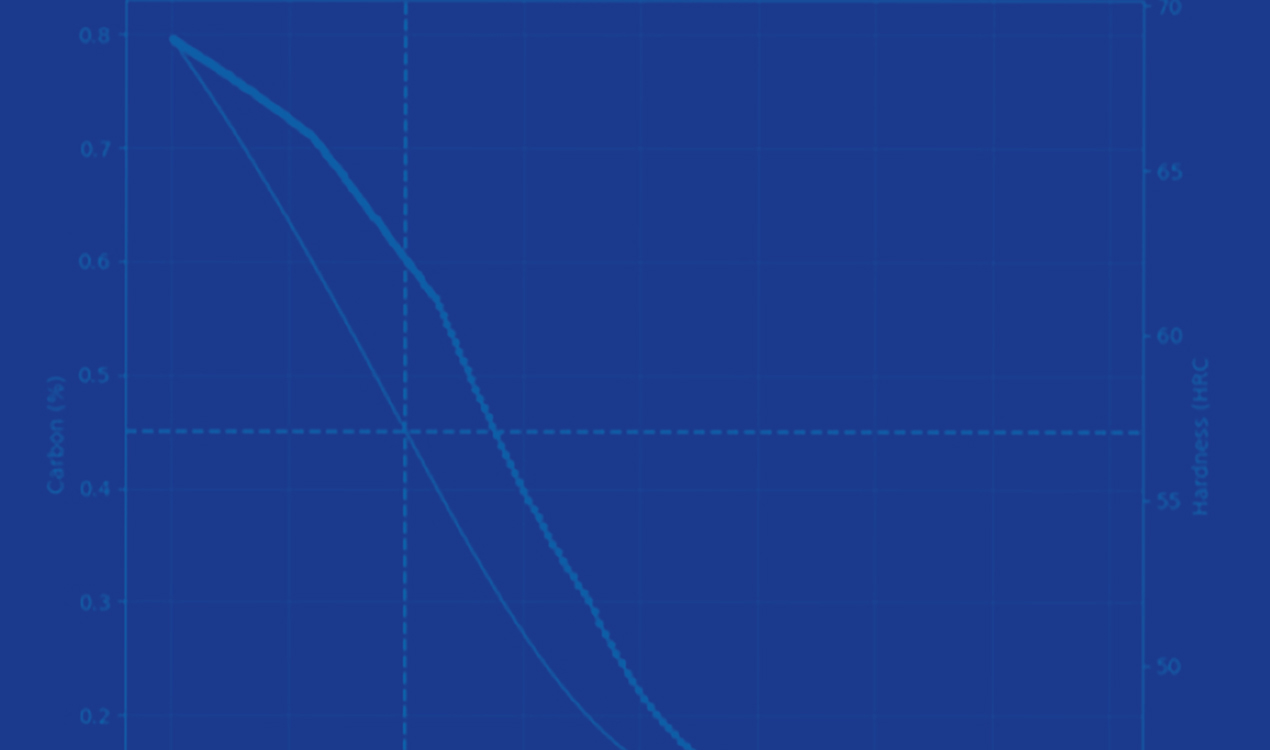

For lean manufacturing principles to work, component designers must consider how their designs integrate with heat treatment, where a significant amount of time and money is currently wasted.

DAN HERRING, THE HEAT TREAT DOCTOR

"Techniques pioneered by IHTS can not only eliminate post-heat treatment machining by incorporating FEA & CFD modeling software to predict distortion of the green part, IHTS can also reduce high alloy material costs to achieve better, longer lasting parts."

Technology is available today that IHTS can help you implement to achieve all the benefits of lean manufacturing, especially if you are forging or heat treating with induction or other single-stream processes.