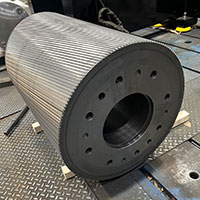

IHTS’s patent pending Dual Austenitizing Temperature (DAT™) Heating process combined with our High Pressure Instant-Impact Quenching process can enable part makers to switch from case carburized steel parts, eliminate long, batch case carburizing furnace cycles and use a low cost, readily available ductile iron cast material and heat treat the part in a single-part flow. Part-by-part heat treatments enable the part manufacturer to fully integrate the heat treatments into their part manufacturing cell – saving both time and energy.

IQDI Products are 8% to 10% lighter by volume than a comparable steel part. Ductile iron with its graphite particles in an iron matrix machines about 30% faster than a steel raw material.

The benefits from an IQDI Product in a fracking pump valve seat are set forth below: